Introduction

Consider the scenario whereby an order cost you $5,000 on a single delivery just because you selected the wrong kind of container. It is not a hypothetical situation, and it occurs to companies across the world when they misinterpret the differences between SOC and COC containers. The industry reports indicate that the costs relating to containers may take up to 15 percent of the overall costs of shipping, and therefore, the decision to use a container or a container type is a business-critical decision that often requires a certificate of conformity.

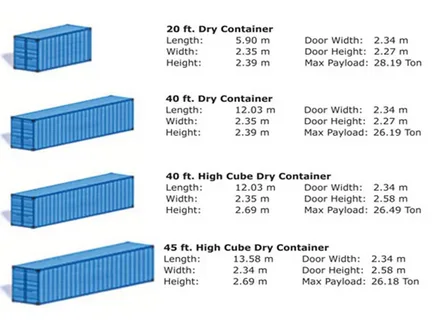

The dimensions of your container will not only influence the cost of shipping and transportation convenience, but will also influence the size of your storage area and the optimization of your cargo. It can be an excavating machine or a bulk piece of furniture; a misjudgment can cost you millions of dollars of the difference between profitable and unprofitable logistics. Just because the box size is different, you will understand the actual cost requirements, and you may have the examples showing what choices you can be sure will work in future shipping.

What are SOC Containers

Shipper-Owned Container (SOC) is described as shipping containers, which are either bought or rented by the shipper instead of the shipping line. Under this type of arrangement, you as a shipper assume ownership and responsibility of the owned freight containers during the entire lifecycle of the container.

SOC containers follow a very simple principle: you own the asset. After obtaining the container, you can have a multipurpose container to use in future shipments, you can keep the container on your premises, and you can even make some adjustments to the container depending on your needs. The shipping line just picks your container and carries it like any other cargo they would carry in a cargo container.

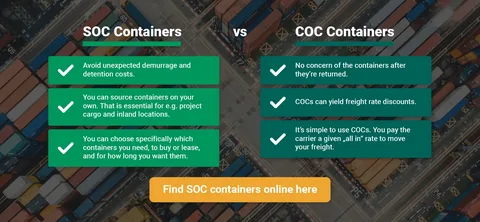

Advantages of SOC Containers:

SOC containers present important benefits of flexibility. You are able to pack your goods at your own pace without having to worry about the time frame set by the carrier on how your goods have to be delivered, and you do not have to be limited to the container return schedule of the shipping line. The flexibility is especially important to companies whose shipping schedules are not regular or those that need to store goods over an extended time.

The other notable benefit is cost control. SOC containers can be expensive, but they can be cheaper to shippers who can sign on to multiple shipments, sharing the purchase price with freight forwarders. You even save on many fees to carrier-owned containers, such as the detention and demurrage fees the container is owned by.

Challenges of SOC Containers: It is crucial to document all aspects of usage to prevent issues.

Its main disadvantage is high start-up capital. Buying new containers is estimated to be between 3,000-6,000 dollars per unit, and leasing is usually based on long-term contracts. Maintenance, repair, and regulatory compliance is also your responsibility and could be expensive and time-consuming distant or remote location carrier company.

Another issue is container positioning. As opposed to COC containers, which carriers handle around the world, you have to organize empty container repositioning, which is costly and logistically challenging, particularly for one-way shipment, especially during customs clearance, container liner.

What are COC Containers

A shipping container that is owned and operated by the shipping line or carrier is known as a Carrier Owned Container (COC). Such containers are also part of the carrier service offering, and the shipping line reserves complete ownership and operational control in compliance with safety regulations.

COC containers are used in the integrated system of the carrier. The container is supplied by the shipping line along with the loading of your cargo, delivery to the destination, and the delivery of the shipped container back or to a different position. The customer will usually expect you to take care of your duties until the moment that you unpack your goods and hand back the empty container before the deadline indicated.

Advantages of COC Containers:

Convenience is the greatest benefit of COC containers. All the logistics of containers are dealt with by the carrier, including the supply of clean certified containers as well as the management of their locations globally, often in partnership with the manufacturer to prove compliance. It is a perfect set-up with small to medium-sized shippers who may not possess the resources or volume of shipment to warrant owning a container.

Another important advantage is risk mitigation. The carrier takes responsibility for the maintenance of containers, regulatory compliance, and most of the operational risks. You are insured against any unforeseen repairs, theft, or damage to the container itself own containers.

COC containers are also more available globally. Newer shipping companies also have container fleets spread all over the world, meaning that they are available wherever the trade route and port are, which proves very beneficial to the businesses that have various business destinations and products to comply.

Disadvantages of COC Containers:

The first weakness is the lack of control. You have to operate within the schedules of the carrier, both in terms of pickup and return in various countries, and this can pose operational bottlenecks. Long storage will incur high detention fees, which normally cost between 75 and 300 dollars per day, depending on the port and time individual or independent business.

COC containers can incur hidden costs at a very rapid rate. In addition to the detention fees, there are also demurrage fees for the late pickups at the port, cleaning charges on the contaminated containers, and premium charges in high season when there are fewer containers.

Side-by-Side Comparison: SOC vs COC

| Aspect | SOC Containers | COC Containers |

| Ownership | Shipper owns/leases | Carrier owns |

| Upfront Cost | High ($3,000-$6,000) | Low (included in freight) |

| Ongoing Costs | Maintenance, positioning | Detention, demurrage |

| Flexibility | High control over timing | Limited by carrier schedules |

| Risk | Shipper bears all risks | Carrier assumes most risks |

| Availability | Depends on your inventory | Carrier’s global network |

| Maintenance | Shipper responsibility | Carrier responsibility |

| Best For | High-volume, regular shippers | Occasional, small-volume shippers |

Practical Examples:

The shipment of 50 containers of furniture a month into the US by a furniture company based in China would most probably be advantageous in the use of SOC containers. The volume is worth investing in, and the flexibility is worth the time spent on long loads of bulky furniture.

On the other hand, a smaller electronics shop that orders 2-3 containers every quarter would be better off with COC containers. The small volume is not worth container ownership, and the carrier has a global network that guarantees that it is available among the suppliers.

How to Choose Between SOC and COC

Whenever you choose the type of container to use, it is important to critically consider a number of important factors that directly influence your operational efficiency and costs.

Volume and Frequency Considerations:

SOC containers can be very economical for high-volume shippers (10 or more containers a month). The fixed costs are divided among the shipments, and per-shipment costs are lowered. COC containers tend to have more advantages for low-volume or irregular shippers because of their less capital-intensive nature and the simplicity of operation.

Budget and Capital Structure:

SOC containers are costly to purchase or rent in the long term; hence, they are effective for companies that have access to cash capital or credit facilities. COC containers have their own operational expense model, and the cost is factored into the freight charge; in the process, budgeting will be more predictable.

Geographic and Infrastructure Factors:

Take into account your shipping lines and port facilities. SOC containers are effective in the routes of trade that are well known, and the potential of repositioning containers. Remote ports or developing ports can have limited SOC support capabilities, and COC containers can be more viable.

Timing Requirements:

When it is necessary to have a flexible loading and unloading schedule in your business, or you need an extended storage area, SOC containers give the control required. COC containers could be more effective in time-sensitive operations when the carrier has strict delivery windows, as the carrier has integrated scheduling systems.

Essential Questions for Your Career:

Questions to consider before deciding include. At what time does your shipping provider offer any detention-free COC container time? Does your shipping provider guarantee availability during peak time? Does your shipping provider provide maintenance service on SOC containers in your area of operation? And what is the total cost breakdown, including all the possible fees?

Cost Implications & Hidden Costs

It is important to know the actual cost setup of both types of containers to decide well and ensure that your profitability is not jeopardized.

Upfront Investment Analysis:

SOC containers have high investment requirements, and the newer 40-foot containers cost 4,000-6,000, and the 20-foot containers cost 3,000-4,500. The leasing services are usually 2-5 year contracts with payments of 150-300 dollars monthly per container. COC containers seem to be free, but the charges are fixed in the freight rates, which usually incur fees are charged on a shipment of $200-500 incurred depending on the route.

Ongoing Operational Costs:

Maintenance of SOC containers costs on average between 200 and 400 dollars every year per container, which includes the cost of inspections and repairs, as well as certifications. The cost of positioning empty containers may be as high as 300-1500 with regard to the market conditions and the route.

COC containers create continuous expenses with the detention fees (usually between 100-300 dollars a day following the free days), demurrage fees for the late pickup of the port (75-200 dollars a day), and cleaning fees on the polluted containers (150-500 dollars a time).

Hidden Cost Traps:

The cost of repositioning is normally under-estimated by SOC users, particularly in the case of imbalanced trade lanes, whereby the number of returns cargo is low. Liability cover and insurance on owned containers costs between $50 and 150 per year per container.

The users of COC are often caught by unexpected costs during the peak seasons when the carriers charge emergency surcharges (200-800 per container) or when the time of detention is calculated wrongly because of weekends and holidays.

Real-World Use Cases & Examples

Case Study 1: High-Volume Furniture Importer

A US furniture retailer that imports 40 containers each month from Vietnam changed the COC to SOC containers and cut the annual shipping expenses by one hundred and eighty thousand dollars. The most important issues were the removal of detention fees (an average charge of 8,000 a month), a flexible loading period that lowers the costs of rush production, and the capability to temporarily store in containers during the peak seasons.

Case Study 2: Small Electronics Startup

A technological startup importing four containers a year decided to use COC containers instead of SOC and saved about $25,000 in the first year. The ruling saved the company the cost of purchasing 18,000 containers, maintenance and positioning costs 4,000, insurance and administrative costs amounted to 3,000, and the COC detention expenses only amounted to 1,200 per year.

Port Infrastructure Impact:

Both the SOC and the COC options have the best support services and cost at large ports such as Los Angeles or Hamburg. Nevertheless, in smaller ports of developing areas, the SOC containers might have fewer available maintenance facilities and require more time to position, which makes COC containers more reliable even though the costs might be higher.

Best Practices & Tips

Negotiation Strategies:

In the case of SOC containers, negotiate volume discounts with container manufacturers and look at lease-to-own deals that offer flexibility. In the case of COC, negotiate longer free periods when your season is at its peak and demand all-inclusive freight rates that will not impose any unexpected costs.

Operational Excellence:

Install powerful monitoring solutions in SOC containers in order to utilize them in the most effective way and avoid their loss. Keep an extensive maintenance log and negotiate with certified repair centres in your main shipping areas. In the case of COC operations, establish an internal policy on prompt returns of containers and ensure the records of the condition of the containers to challenge unfair prices.

Risk Management:

SOC users are to ensure that they have extensive insurance cover and that they have emergency repair policies. Establish contact with container leasing entities to provide reserve capacity during the seasonal times. A supply chain planning that takes into account capacity due to any disruption should include buffer time to accommodate possible container availability challenges among the carriers and develop a good relationship with various carriers in case of disruption among the COC users.

Technology Integration:

Use container tracking technology and warehouse management systems to maximize container movements. Use of automated detention time and maintenance schedules would avoid expensive oversights and enhance operational performance.

Common Mistakes to Avoid

Financial Miscalculations:

Most companies fail to consider the overall cost of ownership of SOC because they just look at the purchase or lease value, and they do not include maintenance, positioning, and administrative overhead costs, nor do they consider the test results. On the other hand, the COC clients also do not plan how to budget the expenses of detention and demurrage, which results in sudden increases in costs.

Operational Oversights:

In unbalanced trade paths, SOC users mostly fail to consider the multifacetedness of the global container positioning. Poor maintenance planning may lead to container failure during inspection and delay of shipments.

Free periods and grace days are another issue that is typically misinterpreted by the users of COC, resulting in unwarranted arrest fees. Lack of effective communication with carriers concerning pickup and delivery schedules causes extra expenses and disruptions in operations.

Contract Clarity Issues:

Unclear contractual terms associated with responsibility, maintenance, and cost are the sources of conflicts and unforeseen costs. There should be proper documentation of the conditions in the containers before engaging either one, as there must be clear documentation of the terms of returns and the fees before engaging in either of them.

Strategic Misalignment:

The tendency to select the types of containers only according to the short-term cost and not long-term development of the business, seasonal changes, and the complexity of the supply chain frequently results in less than optimal decisions that are costly to change.

Conclusion

In order to be competitive in the shipping business, you need to understand the details of SOC and COC containers and operate them in such a manner that would help minimize expenses. SOC containers are highly adaptable and manageable; therefore, they are applicable to large shippers who can manage the start-up expense and complexity of the process. COC containers are not only convenient but also less capital-intensive due to their small business size or oddly shaped shipping frequency. Such a decision, at some point, would be a question of personal volume, access to capital, and operating and risk needs. It is also worthwhile to compare the present trends in shipping and the actual cost of each option and consult a capable logistics service provider to make the choice that will help achieve the business objective.

FAQ Section

What is the meaning of detention in container shipping? Detention: This is a fee that is charged when a container of COC is detained due to exceeding the time frame mentioned as free in carrier after the cargo has been discharged. The average free time is a period of 3-7 days, beyond which the rate of 75-300 dollars is charged daily until the empty container is returned to the specific point.

Is it easy to change SOC to COC? Switching can be done, but very carefully planned. The SOC to COC business entails selling or rebranding your owned containers and refreezing freight agreements. COC to SOC converters are very expensive in terms of capital, and they need to set up maintenance facilities. The two transitions normally require 3-6 months to do so effectively.

Is it more environmentally friendly? High-volume shippers can find SOC containers more eco-friendly since they make the use of such containers more efficient and decrease the amount of empty positions. Nevertheless, a system of global optimization of carriers means that COC containers have an advantage in terms of overall fleet utilization of the carriers through multiple customers.

Who does the law hold responsible for the damage in SOC vs COC? Under SOC containers, the shipper will be dealing with container damage, theft, or loss, and thus must have insurance to cover such cases. In the case of COC containers, the carrier usually carries the risk of the containers, but the damage to cargo is the liability of the shipper unless it can be proved that this was caused by defects in the containers.